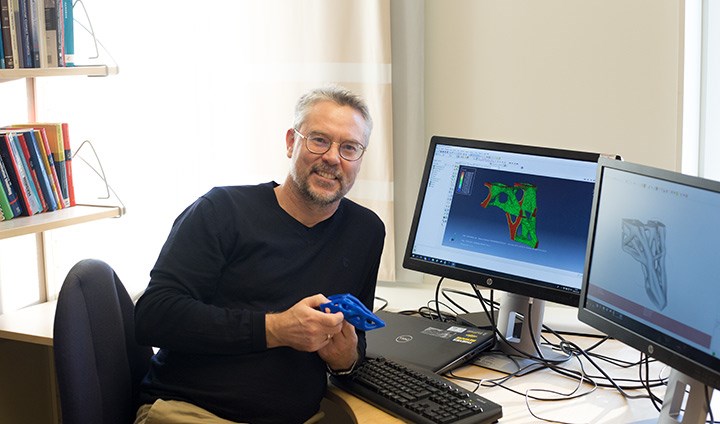

Niclas Strömberg - new professor 2020

Niclas Strömberg is professor of mechanical engineering and he has many years of research experience in computational mechanics and design optimisation. Currently, much of his research concerns how to improve design optimisation for additive manufacturing by using methods from machine learning and how to optimise lattice structures for additive manufacturing.

1968 Born in Ljungby, Sweden

1997 Obtained his PhD in engineering mechanics at the Institute of Technology at Linköping University with his thesis Continuum Thermodynamics of Contact Friction and Wear

2005 Docent in engineering mechanics at the Institute of Technology at Linköping University

2010 Professor of machine design at Jönköping School of Engineering

2020 Professor of mechanical engineering at Örebro University

“One of the bottlenecks, when using topology optimization in design for additive manufacturing, is the transition from the optimal density solution to a CAD model. Currently, a lot of improvements in this area is happening in our commercial software platforms. During the last two years, I have developed a methodology using support vector machines, which automatically creates an implicit surface that serves the purpose of a CAD model. In addition, detailed design optimisation of the implicit surface is easily done by morphing and design of experiments. The proposed methodology was recently published in an international journal and presented at an international conference on simulation for additive manufacturing.”

Niclas Strömberg began his research career in 1993 as a doctoral student at the Institute of Technology at Linköping University, developing models and computational methods for contact problems involving friction, wear and heat generation. After his PhD in 1997, he continued this work, together with two new doctoral students, by developing models and computational methods for fretting fatigue and gear dynamics.

In 2005, he was recruited to Jönköping School of Engineering to structure activities within computational mechanics and design optimization. In his role as head of research, he initiated along with five doctoral students, research within design optimization (topology optimisation, metamodel-based design optimisation and optimization with uncertainties) and (thermomechanical) simulation of residual stresses in castings, while research with contact mechanics continued with the study of thermal stresses in brake discs.

At Örebro University, Niclas Strömberg has in addition to teaching on the Master of Science programme in Industrial Engineering and Management, focused his research on design optimisation for additive manufacturing, in particular on improving the design optimisation process by using methods from machine learning, but also on how to functional grade lattice structures by design optimization.

“The design optimization procedure is initiated by performing topology optimisation for a particular design domain. The optimal density solution is then classified by using support vector machines in order to create an implicit surface which easily can be modified by Boolean operators and blended with lattice structures that are well suited for additive manufacturing. By following this procedure, we can quickly come up with several potential concepts, we call this procedure for generative design.”

In addition to his academic career, Niclas Strömberg has experience working as a mechanical engineer at ABB Atom, Saab, ERAB (now Dynamore) and IKEA.